06

2024-09

什么是亞克力?

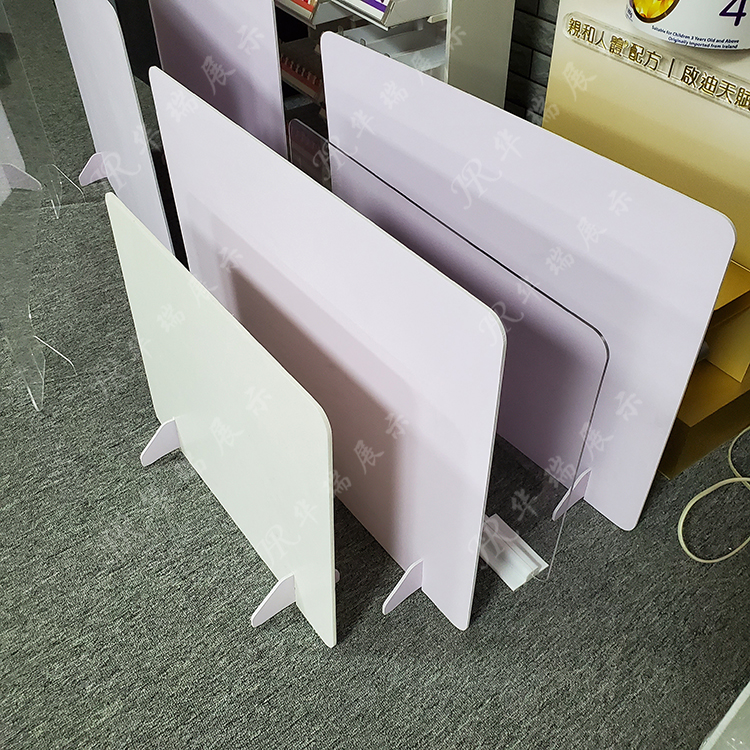

亞克力板材

亞克力的中文名稱由英文Acrylics音譯而來,中文俗名有亞克力、阿克力。是丙烯酸類和甲基丙烯酸類化學(xué)品的通稱。包括單體、板材、粒料、樹脂以及復(fù)合材料。亞克力板由甲基烯酸甲酯單體(MMA)聚合而成,即聚甲基丙烯酸甲酯(PMMA)板材有機(jī)玻璃,是一種經(jīng)過特殊工藝加工的有機(jī)玻璃。有“塑料皇后”之美譽(yù)。亞克力的研究開發(fā),距今已有一百多年的歷史。

1工藝性能

亞克力板具有水晶一般的透明度,透光率達(dá)92%以上,用染料著色的亞克力板又有很好的展色效果,此外,亞克力板:具有極佳的耐候性,較高的表面硬度和表面光澤以及較好的耐高溫性能。亞克力板有良好的加工性能,按生產(chǎn)工藝可分為澆鑄型和擠壓型兩種。既可采用熱成型(包括模壓,吹塑和真空吸塑),也可用機(jī)械加工方式如鉆、車、洗、切割等。用微電腦控制的機(jī)械切刮和雕刻不僅使加工精度大為提高,而且還可制作出比傳統(tǒng)方式更精美的圖案和造型。另外,亞克力板可采用激光切割和激光雕刻,制作效果奇特的制品。

硬度是最能體現(xiàn)澆注亞克力板生產(chǎn)工藝和技術(shù)的參數(shù)之一,是品質(zhì)控制中的重要一環(huán)。硬度能反映出原料MMA純度、板材耐候性以及耐高溫性能等。硬度直接影響到板材是否會收縮彎曲變形,加工時(shí)表面是否會出現(xiàn)皸裂等情況。硬度是評判亞克力板品質(zhì)好壞硬性指標(biāo)之一。澆注亞克力板具有目前最高的硬度指標(biāo)平均達(dá)洛氏硬度值90度。

亞克力板且有極佳的耐候性,尤其應(yīng)用于室外,居其他塑膠之冠,并兼具良好的表面硬度與光澤,加工可塑性大,可制成各種所需要的形狀與產(chǎn)品。其板材的種類繁多色彩豐富(含半透明的色板),另一特點(diǎn)是厚板仍能維持高透明度。

2技術(shù)指標(biāo)

亞克力燈箱

具有良好的透光性,是無色透明有機(jī)玻璃板材,透光率達(dá)92%以上;具有優(yōu)良的耐候性,對自然環(huán)境適應(yīng)性很強(qiáng),即使長時(shí)間在日光照射、風(fēng)吹雨淋也不會使其性能發(fā)生改變,抗老化性能好;加工性能良好,既適合機(jī)械加工又易熱成型;亞克力板可以染色,表面可以噴漆、絲印或真空鍍膜。無毒,即使與人長期接觸也無害,燃燒時(shí)產(chǎn)生的氣體不產(chǎn)生有毒氣體。且有極佳的耐候性,耐酸,耐堿。板材的種類繁多色彩豐富(含半透明的色板),另一特點(diǎn)是厚板仍能維持高透明度。

技術(shù)指標(biāo):

密度:19kg/dm3;透光率:92%;沖擊強(qiáng)度≥16kg/cm3;拉伸強(qiáng)度≥61Kg/m3;熱變型溫度≥78℃;熱軟化溫度≥105℃;規(guī)格:1.22×2.44、1.22×1.83m、1.25×2.5m、2×3m、2.05×3.05m......;厚度:2mm-50mm。

1、無可比擬的戶外耐候性,面板涂覆高濃度紫外線吸收劑,金屬底座噴涂進(jìn)口汽車漆,可保長久耐侯,不褪色,使用年限長達(dá)5~8年。

2、透明板如水晶般清澈透明,是玻璃產(chǎn)品的200倍,幾乎沒有斷裂的危險(xiǎn)。

3、表面光澤高、光滑平整,透光率高達(dá)93%,透光極佳、光線柔和、璀璨奪目。

4、有透明、半透明、乳白等多種顏色和各種不同表面效果,采用新型聚脂材料,經(jīng)熱曲成型或平面鑲邊,金屬托底內(nèi)置光源,極具視覺沖擊力。

5、加工性能優(yōu)良;熱成型 制作視覺效果突出的招牌、標(biāo)識時(shí)加工簡便,成本合理。工藝精美,全字體呈鏡面效果,底座無褶皺,無接縫,所有鉚固件不外露。

6、綠色環(huán)保、廢舊料可以被徹底回收,再生利用簡便易行。透光性能好,相應(yīng)減少光源產(chǎn)品,省電電,降低使用成本。

7、優(yōu)異的表面硬度和抗劃傷性能,產(chǎn)品對內(nèi)置光源具有良好的保護(hù),延長光源產(chǎn)品使用壽命。

8、良好的耐化學(xué)品性能,優(yōu)于大多數(shù)其它塑料材料。

9、容易清潔、維護(hù)、保證招牌、燈箱外觀常年如新,合理性設(shè)計(jì),防雨防潮,開啟式結(jié)構(gòu),便于維修。

10、耐燃性:不自燃并具自熄性。

3型材特性

亞克力澆鑄板:分子量高,具有出色的剛度、強(qiáng)度以及優(yōu)異的抗化學(xué)品性能。這種板材的特點(diǎn)是小批量加工,在顏色體系和表面紋理效果方面有無法比擬的靈活性,且產(chǎn)品規(guī)格齊全,適用于各種特殊用途。

亞克力擠出板:與澆鑄板相比,擠出板分子量較低,機(jī)械性能稍弱。然而,這一特點(diǎn)有利于折彎和熱成型加工,在處理尺寸較大的板材時(shí),有利于快塑真空吸塑成型。同時(shí),擠出板的厚度公差比澆鑄板小。由于擠板是大批量自動(dòng)化生產(chǎn),顏色和規(guī)格不便調(diào)整,所以產(chǎn)品規(guī)格多樣性受到一定的限制.

多年以來,熱成型一直是亞克力板最具創(chuàng)造性的用途之一。隨著加工技術(shù)的改進(jìn)和產(chǎn)品品種、性能的豐富完善,相對于其它傳統(tǒng)廣告招牌材料,亞克力的加工更加簡便、安全,產(chǎn)品的性價(jià)比也更為合理。

一、耐候性:亞克力板具有優(yōu)異的戶外耐候性,可以被認(rèn)為是所有塑料材料中最好的。正常的戶外使用條件下,設(shè)計(jì)、加工合理的亞克力板招牌,經(jīng)過10年的使用期,其機(jī)械強(qiáng)度也不會降低,外觀不會明顯改變。

二、色板的透光性能:高品質(zhì)的亞克力板都會按照嚴(yán)格質(zhì)量標(biāo)準(zhǔn)生產(chǎn),確保不同批次、不同板材都具有相同的色澤。由于色板的顏色是沿整個(gè)板材厚度方向均勻分布,所以反牌表面的磨痕被光照時(shí)會對外觀顏色產(chǎn)生一些影響。

大部分亞克力色板的透光度都會隨板材厚度的增加而降低,對于某些標(biāo)識方面的應(yīng)用,這種效果可能會產(chǎn)生不良影響-比如,在同一標(biāo)識同時(shí)用到不同厚度的色板時(shí),會有明顯色差。這種情況,可以考慮采用某些固定透光度顏色的亞克力色板,雖然板材厚度一同,但呈現(xiàn)相同的顏色透光度。

亞克力板材和型材:管棒、普通板、透明板、有色板、紋理板、實(shí)心平板、多層板、磨砂板、瓦浪板、抗沖擊板、特級板、國標(biāo)板、特厚板、變色板。

4應(yīng)用范圍

亞克力板的研究開發(fā)和使用,距今已有一百多年的歷史。1880年甲基丙烯酸的聚合性為人知曉;1901年聚丙酸脂的合成發(fā)研究完成;1927年運(yùn)用前述合成法嘗試工業(yè)化制造;1937年甲基丙烯酸甲脂工業(yè)制造開發(fā)成功 ,由此進(jìn)入規(guī)模化制造,因其具有優(yōu)異的強(qiáng)韌性及透光性,二戰(zhàn)時(shí)期應(yīng)用于飛機(jī)的擋風(fēng)玻璃,坦克視野鏡等,最常見的手機(jī)屏幕就是用光學(xué)級的亞克力制作的。

青島水族館亞克力柱形水箱

亞克力板主要用于雕刻,裝飾,工藝品制作,擠壓型的通常用于廣告招牌,燈箱等制作。PMMA具有質(zhì)輕、價(jià)廉,易于成型等優(yōu)點(diǎn)。它的成型方法有澆鑄,射出成型,機(jī)械加工、熱成型等。尤其是射出成型,可以大批量生產(chǎn),制程簡單,成本低。因此,它的應(yīng)用日趨廣泛,它廣泛用于儀器儀表零件、汽車車燈、光學(xué)鏡片、透明管道等。

在建筑方面,有機(jī)玻璃主要應(yīng)用于采光體、屋頂、棚頂、樓梯和室內(nèi)墻壁護(hù)板等方面。有機(jī)玻璃在高速公路和高級道路的照明燈罩和汽車燈具方面的應(yīng)用也相當(dāng)快。隨著大城市飯店、賓館和高級住宅的興建,采光體發(fā)展迅速,采用有機(jī)玻璃擠出板制成的采光體具有整體結(jié)構(gòu)強(qiáng)度高、自重輕、透光率高和安全性能好等特點(diǎn),與無機(jī)玻璃采光裝置相比,具有很大的優(yōu)越性。

在衛(wèi)生潔具方面,有機(jī)玻璃可制作浴缸、洗臉盆、化妝臺等產(chǎn)品。由于有機(jī)玻璃浴缸具有外觀豪華、有深度感、容易清洗、強(qiáng)度高、質(zhì)量輕和使用舒適等特點(diǎn),得到了廣泛的應(yīng)用。亞克力是繼陶瓷之后能夠制造衛(wèi)生潔具的最好的新型材料。與傳統(tǒng)的陶瓷材料相比,亞克力除了無與倫比的高光亮度外,還有下列優(yōu)點(diǎn):韌性好,不易破損;修復(fù)性強(qiáng),只要用軟泡沫蘸點(diǎn)牙膏就可以將潔具擦拭一新;質(zhì)地柔和,冬季沒有冰涼刺骨之感;色彩鮮艷,可滿足不同品位的個(gè)性追求。用亞克力制作臺盆、浴缸、坐便器,不僅款式精美,經(jīng)久耐用,而且具有環(huán)保作用,其輻射線與人體自身骨骼的輻射程度相差無幾。亞克力潔具最早出現(xiàn)于美國,2008年后已占據(jù)整個(gè)國際市場的70%以上。

亞克力各種時(shí)尚精品,舉凡皮包、 腰煉、手表、高跟鞋、鞋跟、發(fā)飾、胸針、手鐲、鈕扣、耳環(huán)、項(xiàng)煉、戒指、吊飾、相框、文鎮(zhèn)等等種類多有無限發(fā)展延續(xù)的空間。因亞克力材料加工可塑性高又有良好的表面硬度與透明光澤,常被設(shè)計(jì)師拿來與各種不同材料搭配應(yīng)用在各式精致容器設(shè)計(jì)上,添增容器質(zhì)感及實(shí)用性,如口紅及化品等精致容器,其它如按摩器、珠寶盒、扇子等生活用品。發(fā)揮亞克力材質(zhì)的清涼感覺,結(jié)合創(chuàng)意設(shè)計(jì)讓亞克力材料完美呈現(xiàn)在各式各樣的流行精品里。